Powder Metallurgy by Osweypm

Your Metal Parts Manufacturing Resource

ShenZhen’s leading Powder metallurgy parts (sintered metal parts) manufacturer and supplier of powder metallurgy products for different industries and equipment components.

From Powder Metallurgy(PM) to Metal Injection Molding(MIM),we use advanced powder metal manufacturing techniques and rigorous in-process testing to ensure that the strength,corrosion resistance and mechanical properties of our powder metallurgy products meet your application requirements and exceed your expectations.

We continue to introduce advanced technologies and processes into our manufacturing centers,and to help more and more customers use the latest technology to ultimately produce more durable and cheaper products.From the beginning of the design process to the end of mass-produced parts,rigorous testing is performed to ensure that the products we manufacture exceed performance expectations.Always keeping our customers’ projects at a greater advantage in the marketplace,relocating your production to an owseypm manufacturing plant could yield greater advantages.

Metal Parts Manufacturing Services

By utilising the infinite possibilities of Osweypm metal powders, our desire is to make more with less and to reduce your costs.

Powder Metallurgy(PM)

Metal Injection Molding

Precision Machining

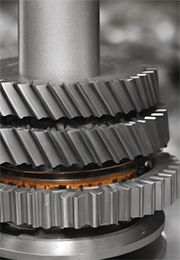

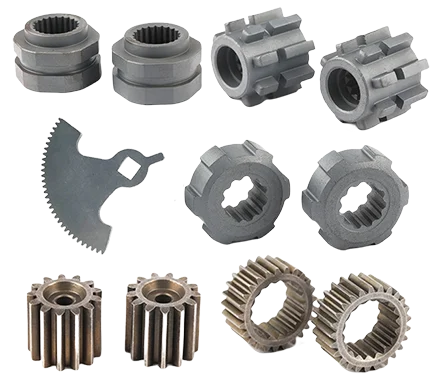

Powder Metallurgy(PM)

Sintered parts(PM)

Sintered parts process has a material tilization rate of more than 96%,reducing energy consumption,which is good for the environment and saves you money on your projects.

The powder metallurgy process offers a number of amazing advantages,with products that can be used directly after sintering without secondary processing,near-perfect surface finishes and mechanical properties that work well in extreme environments.

Metal Injection Molding

Metal injection(MIM)

Integrate two completely different machining processes (plastic injection molding and powdered metal materials) into one,obtain low-cost,complex shaped stainless steel,nickel,iron,copper,titanium and other metal parts with excellent mechanical properties by plastic molding.

Metal Injection Molding (MIM) is a highly efficient,advanced manufacturing process for producing parts with complex geometries and is suitable for high-volume manufacturing.

Precision Machining

Precision machining

Precision machining is an economical and reliable method of mass production, has reasonably good tolerance consistency.Save you time by allowing you to get a wide variety of different parts from a single supplier.

Precision machining can fulfil advanced dimensional requirements that cannot be achieved by other processes.

- Cylindrical grinding with tolerances down to ±0.00003in(0.006mm).

How to Work With Us

Upload a Drawings File

Get Quote with Osweypm

Manufacturing Begins

Parts are Shipped!

Want to change your supply chain? We’ll get you the lowest cost.

We offer fully customizable solutions, from mold design evaluation and first samples to series production. We provide full engineering support to customers.

Unlimited Applications of Powder Metallurgy

What Our Customers Say

Powder Metallurgy Manufacturing Technology and Insights

Pressing Process in Powder Metallurgy Manufacturing

The pressing process of powder metallurgy involves pressing a material in powdered state into a specified shape by means of a press, just as flour is poured into a mold to make bread. The powder is pressed into a mold and under…

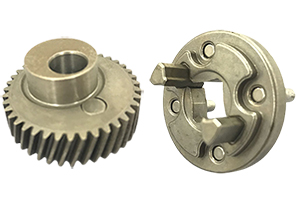

Electric drying rack gear box:Smoothly Rising and Falling

Electric drying racks continue to evolve with technology With the wide application of smartphone APP control, many home products are also changed into intelligent and electronic, connecting home products with mobile phones to achieve remote control. Thanks to the technological development of…