Osweypm’s with 14 years of metal powder manufacturing technology in MIM, PM, etc., offers customized powder metallurgy manufacturing capabilities for any industry. We aim to make your products more cost-effective, reliable, and keep your projects at the forefront of the market!

Advanced Technology Drives Powder Metallurgy Manufacturing Capabilities

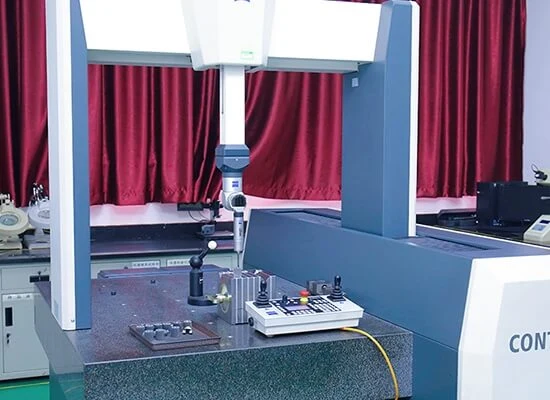

Quality

Osweypm features 3D coordinate measurement (two-dimensional measuring instrument), density scales, hardness tester, resonant inspection, salt spraying tester, and gear measurement systems for all your powdered metal needs. Advanced testing equipment and quality testing bring greater advantage to your market.

Production Facility

The Osweypm Manufacturing Facility was designed from the ground up to maximize cost-effectiveness, flexibility, speed, and quality of manufacturing. We have rebuilt a green, clean, state-of-the-art manufacturing plant and added waste and pollutant treatment facilities to reduce environmental pollution.

Sintering

Our furnaces are equipped with atmosphere controlled sintering capabilities and can sinter up to 2600° F,It is then cooled to provide the strength and properties needed for your powdered metal parts.We have also designed a closed loop cooling system to minimize the impact on the environment.

Secondary Capabilities

Generally, sintered workpieces can be used directly. We offer secondary processing capabilities, including: vibratory finishing, rust inhibiting dip, oil impregnation, assembly, sinter bonding and honing, heat treatment, high energy tumbling, hardening, surface hardening, oil immersion, and corrosion resistance.

Machines Machining Center

Our machining center’s capabilities range from drilling, grinding, heat treatment, high-energy tumbling, and many more. This saves you time by allowing you to obtain a wide variety of different parts from a single supplier. With our manufacturing know-how, we ensure that the other parts are exactly what you expect!

Product Assembly

Advance assembly can reduce precision errors in the parts, thereby minimizing problems and difficulties during the assembly of the entire machine, and eliminating assembly tolerances. It can also lower production costs for customers and consistently enhance the efficiency of their machine assembly process.

What is Advanced Manufacturing Capability?

Advanced manufacturing capabilities refer to the variety of powdered metal processes, equipment, and resources available to produce products. In terms of manufacturing capabilities, our manufacturing facility in Shenzhen continues to push the boundaries of what is possible with powdered metal technology. Osweypm supplies metal parts to many different industries, and our exposure to a wide range of end-uses allows us to take a success story from one market and apply the technology to other markets we serve. To fuel our growth and take us to the next level, we have dedicated some of our manufacturing facilities to our R&D center. These facilities allow us to take full control of the metallurgical engineering process and provide better advanced manufacturing solutions to our customers.

Value-based advanced manufacturing equipment.

The growth at Osweypm comes from combining our experience in mold design and development, compaction, and sintering with our secondary processing capabilities.

Our smart engineers are capable of producing complex powdered metal products while remaining at the forefront of the metal fabrication industry.

From powder metallurgy (PM) to metallurgy injection molding (MIM), and machine machining, with our advanced dimensional inspection equipment, Osweypm can provide reliable, lower-priced metal components and save your procurement time.

Manufacturing is a constantly changing industry. The emergence of new technologies and changes in demand require advanced manufacturing capabilities to keep up.

Advanced manufacturing equipment guarantees that research and development and production will be carried out simultaneously, which is also an important advantage that sets us ahead of our peers!

Advanced quality testing equipment for metal parts.

We use new materials, new mold concepts, and new testing equipment, and then bring the concepts to the production floor for trial use. Through advanced testing equipment, and sound quality testing standards, we are constantly introducing new and innovative products, which translates into a competitive advantage for both parties.