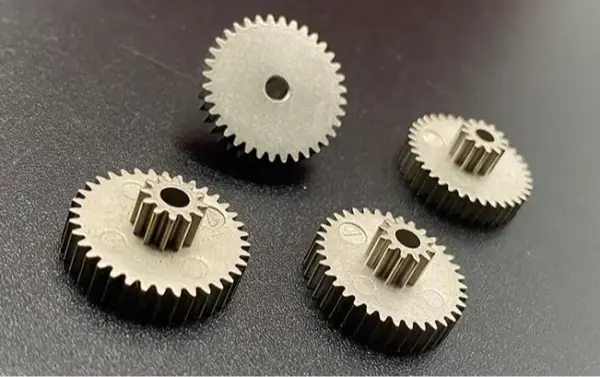

Gears are the most widely used in a variety of electric machinery, is the basic powder metallurgy products in the machinery industry, electric motors, transmission boxes, transmissions need gears as a bridge. Powder metallurgy gears are widely used, mainly because it can be shaped without other processing, no scrap metal generation, low manufacturing cost, high dimensional accuracy, good wear resistance, smooth surface also has self-lubricating properties, Osweypm as engaged in powder metallurgy for more than ten years manufacturers, has accumulated a wealth of experience in manufacturing gears, we believe that powder metallurgy manufacturing gears have the following advantages:

Low Waste Processes

The material can be used more than 95% efficiently in the production of gears, which also protects the environment, and can be produced in a “zero-waste” way, meaning that limited material can be used to the maximum, saving material and reducing production costs.

High product consistency

The consistency of powder metallurgy gears is very stable, this is because powder metallurgy gears are produced by mold pressure molding, so you can control the pressing pressure and mold precision to ensure the consistency of gear precision. Under normal production conditions, the service life of one pair of molds can reach 150,000 to 200,000 gears.

Enhanced physical properties

As traditional hydraulic presses are gradually being replaced by mechanical presses, the ability of the powder metallurgy process to control the density of the workpiece can be improved, and the sintered parts have the physical characteristics of high density and high strength. Gears can be manufactured to operate in extreme environments with high and low temperatures and high pressure environments, increasing the life cycle of the application.

Excellent appearance

In powder metallurgy production, the cavities have a very high finish in order to facilitate release from the mould after forming, so that the gear parts are manufactured with a very good surface finish, which has the advantage of reducing surface friction and allowing the parts to work more reliably.