Electric drying racks continue to evolve with technology

With the wide application of smartphone APP control, many home products are also changed into intelligent and electronic, connecting home products with mobile phones to achieve remote control. Thanks to the technological development of IoT and AI artificial intelligence, electric drying racks are also gradually upgraded into intelligent, and remote control of timed drying, UV disinfection, lighting, adjusting the rise or fall of the drying racks according to the angle of the sun’s rays and so on are now possible.

How does the electric drying rack work?

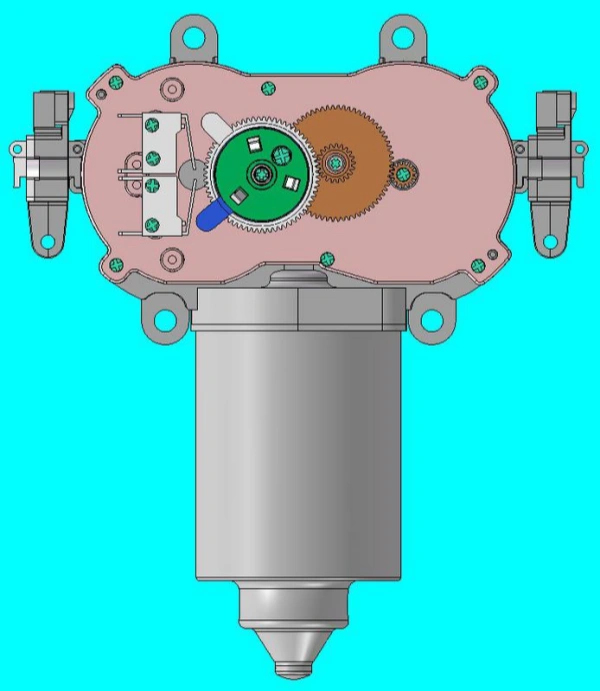

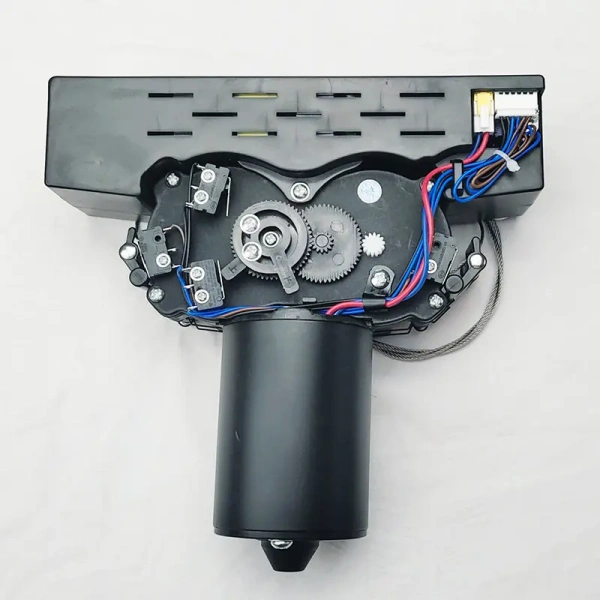

Ascending and descending: The electric motor drives the steel wire rope through the gearbox , the steel wire rope is connected to the drying rack, and the different rotating direction of the electric motor realizes the function of ascending or descending of the drying rack.

Lighting, drying , and UV sterilization functions are controlled by the main board to turn on or off.

How to apply powder metallurgy gears in electric drying racks?

Nowadays, most motors can be integrated with a gearbox, eliminating the need for an additional transmission box. The motor is connected directly to the gearbox, which consists of various gears such as planetary wheels, helical gears, and gear bearings. Electric drying racks typically need to withstand a minimum tension of 40KG. Therefore, the power of the motor and the reliability of the gearbox are crucial factors and core indicators for electric drying rack projects.

Why do electric drying racks use powder metallurgy gears?

As electric drying racks are usually installed at a height of more than 2 meters, the noise is negligible. Therefore, powder metallurgy gears are used whenever possible when designing gearboxes. Powder metallurgy gears have a densification of more than 96% and the density of the gears after sintering is uniform. The polished surface also helps reduce friction, ensuring reliable power output. Powder metallurgy gears perform well in high and low temperature environments and can be applied to projects without the need for secondary machining after sintering. Gears made by this process offer significant cost benefits in mass production. It is because of these advantages that manufacturers of electric clothes drying racks heavily rely on powder metallurgy gears.

Osweypm Powder Metallurgy Explored in Electric Drying Racks

How to make electric drying racks withstand more weight and have a reliable running time? The use of high-quality powder metallurgy products can ensure that the electric clothes drying racks work properly. The right material formula can make the powder metallurgy products withstand more torque and tension. Sintering is also a very important step as it can eliminate the internal molecular gaps and meet the requirements of high-density, high-strength, high-precision, and anti-impact. This will allow the quality of powder metallurgy products to meet and exceed customers’ expectations, ultimately winning the market for them.

Powder metallurgy parts used in electric drying racks:Gearbox body,Miter gears,Planetary gears,Helical gears,Eccentric gears,Adjuster gears,etc.