With the popularity of robots and smart homes, gears of powder metallurgy process are used in more and more industries, the process’s unique low energy consumption, low waste, low cost and high physical properties for many markets in large quantities, such as automatic curtains, AI robots, aerospace equipment, and many other fields, the gears can be said to be an indispensable part of the modern intelligent, but there are also a lot of imperfections, Osweypm engineers and we learnt about the limitations of the powder metallurgy gears together:

- To demonstrate the superiority of powder metal forming technology, it is usually necessary to produce large quantities, such as 5,000 pieces or more,in order to demonstrate the superiority of powder metal forming technology, large production runs of, for example, 5,000 or more pieces are usually required, and in small batches, the production costs of powder metallurgy may rise

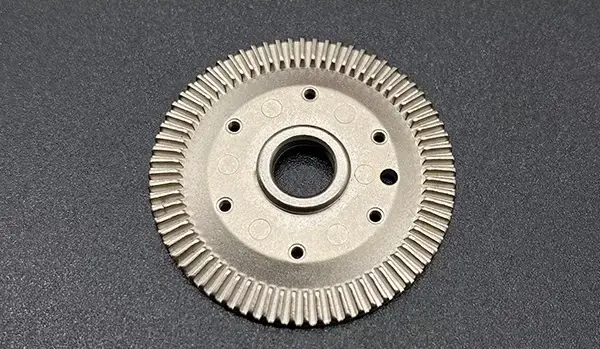

- The size is limited by the press, generally the tonnage of the press is between 60-630 tons, the projected area of the workpiece cannot be too large due to the limitation of the pressing capacity of the press, generally gears with a diameter of 100mm or less can be produced.

- Powder metallurgy gears are limited by the structure, due to the structure of the mold, generally not suitable for the production of worm gears, herringbone gears and helical angle greater than 35 ° helical gear. Helical gears are generally recommended to design the helix angle within 15°.

- Because of the limitations of extrusion pressure and molding density during compression molding, and in order to adapt to the shape in the mold, powder metallurgy gears should not be made too thick structure.