Application Scenarios of Electric Curtains

The progress of science and technology brings more convenience to people, now, just touch the button in the APP or voice control, you can open or close the curtains, no need to operate manually, children can also easily control the curtains, motorised curtain system can be applied in the home, office and manufacturing workshop, bring a new change in life.

How do motorised curtains work?

Motorised curtain systems are driven by an electric motor that rotates a gearbox, which in turn drives the curtains open or closed. Control methods are generally infrared remote control, APP control, voice control and traditional button control, these control methods are different but do not affect the function of the curtains, most of the current motorised curtains are hidden, the control host can not be seen on the outside, and will not affect the original home style!

Powder metallurgy products in the application of electric curtains

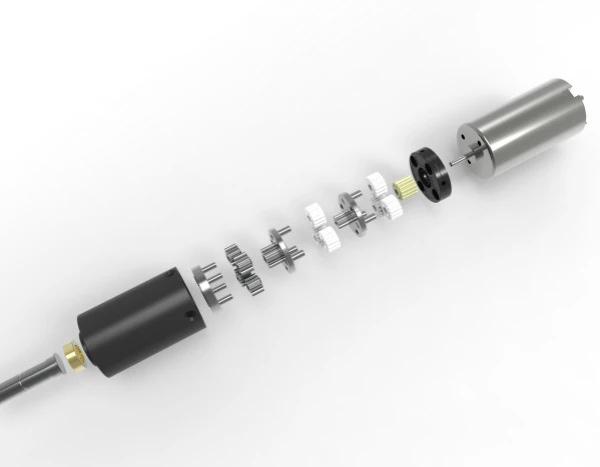

Introduced above, the electric curtains are driven by the internal gearbox, the gearbox is composed of many gears inside a set of complex systems, the quality of the gear directly affects the life cycle of the electric curtains, the noise level, the reliable working time,

the gear box gear can be said to be the core of a system, the gear can not work properly when the whole system is faced with the shutdown, the emergence of the situation for the electric curtain system is a disaster, because a small gear may lose a customer or a market, the situation is This situation is absolutely not allowed to appear, for the manufacturing industry is a kind of low-level error!

Osweypm efforts in motorised curtains

The use of high quality powder metallurgy gears can ensure the stability of the performance of the motorised curtains, Osweypm requires a strict process at every step from the mixing of the material, pressing, sintering and testing, so that the final sintered product can meet the requirements of high density, high strength, high precision and impact resistance, Osweypm also considers environmental factors (such as temperature and air humidity) when designing the gears, air Increased humidity may cause the gears inside the gearbox to rust, which may cause the motorised curtains to stop or become inoperable, our test lab also includes violence test and aging test, what we do is to make sure that our customer’s application won’t be problematic, to make our customer’s project more durable, less post maintenance, to make our customer’s application more competitive in the market, and lastly, to cost less to Producing more powder metallurgy parts, this is what our Osweypm engineers have been exploring and working on!