Introduction to sintering process in powder metallurgy:

Sintering is a powder metallurgy process, the final dimensions of sintered metal parts can only be designed and processed in the final stage, the sintering stage is accomplished by heating a mixed powder mixture in a furnace so that the components of the metal part can finally be combined.

Osweypm applies the following process for the manufacture and supply of powder metallurgy products:

- Sintered Parts: Batch manufacture of high-precision sintered parts by pressing and sintering processes.

- Metal Injection Moulding(MIM): it combines the freedom and flexibility of plastic injection moulding with the durability of metal materials.

Sintering process of powder metals:

The pressed parts are quite fragile and need to de-burr them,move them from the press to the furnace,the work-pieces after sintering have better strength,the sintering furnace is fully automated and can reach temperatures up to 2600°F.

The mechanical properties and dimensions of the metal parts are improved during the sintering process. Sintering allows the product to be designed and customized to the specifications and dimensions required by the user, and the stainless steel material makes the product resistant to high temperatures, corrosion, waterproof and dustproof, and high mechanical strength, which enables it to be used in harsh environments, such as acid and alkali, high temperature and high pressure.

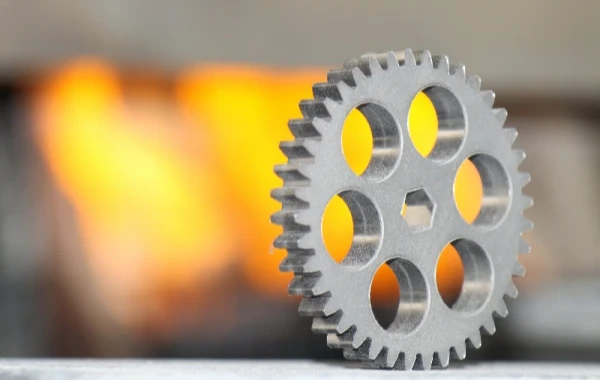

Parts undergoing sintering

Metal parts are automatically sent elsewhere after sintering is complete.

Sintered parts become excellent in terms of mechanical properties.

Related resources: