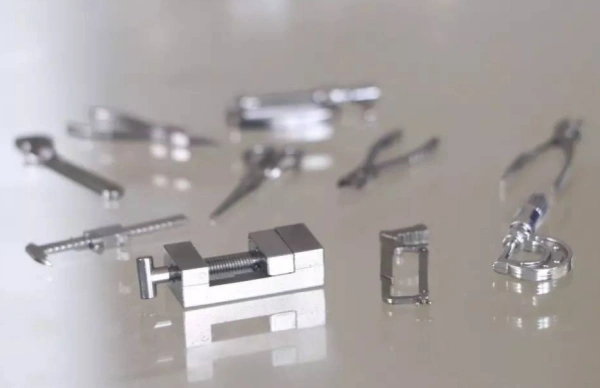

Metal injection molding(MIM) is a comprehensive technology that integrates plastic injection and powder metallurgy processes, using powdered metal injected into the mould and sintered to produce high-density, high-precision parts, the biggest advantage is the ability to design complex shapes of three-dimensional parts, differing from other processes by the absence of cutting, the process steps are simple, there is no scrap metal, there is no or very little secondary machining, and it can produce complex, thin-walled parts that are resistant to changes in ambient temperature. Complex structure, thin-walled parts, resistance to high and low ambient temperature changes, suitable for mass production of fine parts with special requirements.

For the manufacturing industry, less is more, less processing, less material, means lower costs and more help to the environment.

Freedom of design and less machining:

- It is possible to design geometrically complex products without any limitation of shape, and it is possible to form metal parts with complex shapes in a single operation, just as in the case of plastic produ.

- Low energy loss for metal injection in the MIM process, the production process produces almost no scrap metal, the powder material can be directly made into products until the final shape and precise dimensions of the product, there is no or very little machining, the process steps are simple, the economic benefits are obvious, and it is suitable for all kinds of small parts of mass production.

Stable physical properties and reliable working time:

MIM product internal density uniformity, density can reach 95% ~ 99%, higher surface finish, product surface roughness can reach Ra 0.80 ~ 1.6 μm, the production of high dimensional accuracy of the product, generally without secondary processing can be applied to the project, abrasion resistance, excellent physical strength and surface hardness can easily cope with complex applications, increase the reliability of the working time.