Proven methodologies: meet and exceed customer expectations by centralizing the manufacture of powder metal components based on our unique experience.

Using Osweypm’s advanced sintered parts technology and metal injection molding technology, powder metal components can be customized to suit any market,from smart homes,automotive and industrial equipment to medical devices and aerospace. You’ll find powder metal solutions at Osweypm!

Conversion of parts can make a significant difference to your product in the marketplace

Further reductions in parts costs, reduced aftermarket repairs and increased working hours are all part of the revolutionary properties of powder metallurgy.

Powder metallurgy’s design freedom in manufacturing,ability to create complex form structures,and durability in extreme environments make it the best choice for a number of popular industries such as medical, aerospace equipment, and smart electrification markets.

Powder metal products are characterized by “zero waste”,less processing, and very low costs. Converting parts from forgings, castings, and machined parts to powdered metal makes your products lighter, more durable, and more cost-effective.

powder metal components for any market

Smart Home

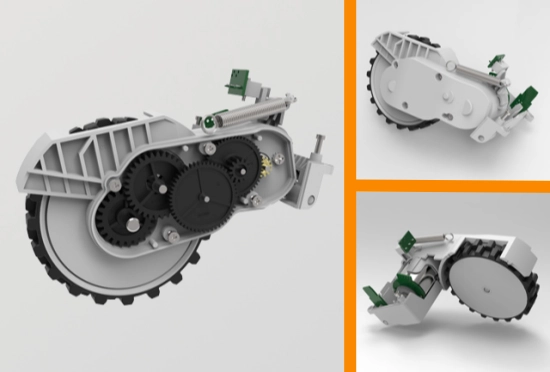

- sintered parts for transmission gearbox

- sintered parts for electric drying rack

- sintered parts for motorised curtains

- sintered parts for electric windows and doors

- sintered parts for electric rolling gate

Household and Lawn

- sintered parts for small engine

- sintered parts for transmission

- sintered parts for kitchen appliances

- sintered parts for clutch components

- sintered parts for transmission gears

- sintered parts for linkages

Medical Equipment

- sintered planetary gear drives

- gearboxes in medical equipment

- surgical instruments and equipment

Automotive and Industrial Equipment

- sintered pistons & connecting rods & bushings & bearings

- sintered parts for steering components

- sintered parts for powertrain components

- transmission gears

Powder metal parts markets served: Medical & Dental,Aerospace & Aviation,Consumer & Industrial,and any industry.

Power Transmission

Spur gears

Bevel gears

miter gears

Planetary gears

Helical gears

pinion gears

Ring gears

Eccentric gears

Sector gears

Adjuster gears

Rotors

Stators

Drivetrain Parts

Bushings

Bearings

Sprockets

Pulleys

Gerotors Component

Sensor rings

Brake yokes

Couplings

Plates

Hardware

Spacers

levers parts

Steering knuckles

Rod guides

Brakes/Metal Hardware

U-Joint components

Geometrically-contoured

Brake parts

Lock hardware

Sliding door hardware

Shock absorber valves

Lift gate components

Roof rack parts

Magnetic motor parts

Sensor rings

Brake yokes

Light mechanical assemblies

Precision Machined Parts

Valve stems

Shafts

Worm Bolt

Driving Axle

*Other machining

Powder Metallurgy Manufacturing Technology

Osweypm applies the following process for the manufacture and supply of powder metallurgy products.

- Sintered Parts: Batch manufacturing of high-precision sintered parts through pressing and sintering processes.

- Metal Injection Molding(MIM): It combines the freedom and flexibility of plastic injection molding with the durability of metal materials.