Precision Machining of End-use Parts

Precision machining centres can be customized to produce a wide range of metal products.Machined parts can be manufactured quickly and speed up your projects, especially when lower quantities are required and parts have advanced dimensional requirements, precision machining is the optimal solution

Precision machining centers allow you to obtain a wide variety of parts from Osweypm’s, saving you time on your projects! We offer fully-integrated manufacturing and finishing, Lead times can be as few as 4 days!

Precision Machining

The focus of precision grinding is to produce very flat, smooth surfaces that work within very tight tolerances.Often used as a finishing process, grinding is an economical and reliable method for obtaining precise tolerances and a beautiful surface finish on manufactured parts.Precision grinding can be used as a final finishing process.

We assess the machining capabilities based on your 2D drawings and ensure that the finished part meets your needs:

- Tolerances on regular parts up to ±0.0008in(0.02mm).

- Cylindrical grinding with tolerances down to ±0.00003in(0.006mm).

* Your part has advanced requirements for certain dimensions that need to be clearly indicated in the 2D drawing or additional documentation.

Machining Capacity

Quality Assurance

Machining Precision

Materials for Precision Machining

- Steel

- Carbon steel

- Tool steel

- Stainless Steel

- Copper

- Brass

- Bronze

- Aluminium

* The dimension we can Machining is from OD Ø 2mm to Ø 55mm,and the maximum length of 200 mm.

* Provide materials according to your requirements, when materials can not be found in the Chinese market, we will choose the most similar materials for you to choose, and provide the chemical composition of the materials.

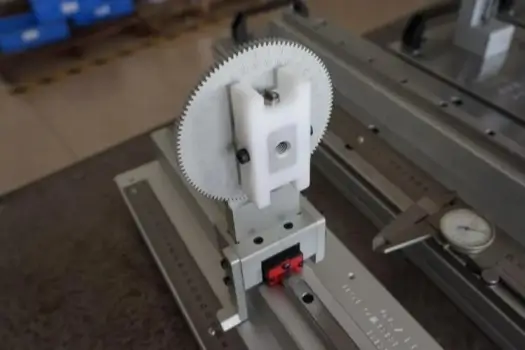

Endless Customisable Precision-Machined Products

We offer the following types of precision machining for use in a variety of industries, including automotive, motorcycle, power tool, and machinery equipment.

Fully Customisable Assembly Options

Advanced assembly reduces or eliminates complete machine assembly tolerances, detects or corrects errors in advance, and ensures that your final product is assembled quickly fast and performs as expected.

- Convenient and Easy to Use: Ready to use when you receive the parts, eliminating the hassle of assembly and shortening your time to market,advance assembly has distinct advantages.

- Outstanding Consistency: the entire set of components is pre-assembled and tested by Osweypm, which can better ensure the function and stability of each part.

- Optimal Economic Efficiency: advanced manufacturing capabilities combined with Osweypm’s flexible assembly lines allow for the direct assembly of manufactured products, reducing the cost of multiple part logistics and transportation, aswell as secondary assembly.

Out of the Box

Quality Assurance

Custom Assembly With Speed and Scale

Advantages to be Gained from Osweypm's Assembly Services