| Part Name: | Metal Parts and Products MIM510 |

| Material: | 316L,davailable: 304,Iron,superalloys,nickel,titanium |

| Process: | Metal Injection Molding Process(MIM) |

| Manufacturing Process: | Molding – Degreasing – Sintering – Grinding – Heat Treatment – 100% Inspection |

| Tensile strength: | ≥500 MPa |

| Yield strength: | ≥180 MPa |

| Hardness: | ≥120 HV10 |

| Density: | ≥7.80g/cm3 |

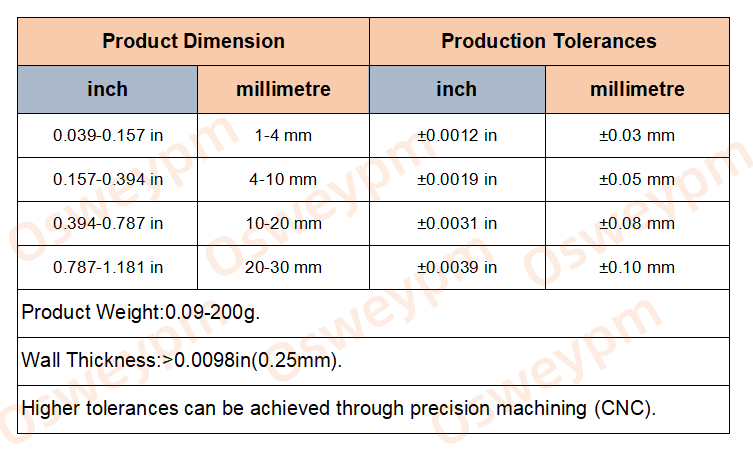

| Tolerances: | general : ±0.0007 in(±0.002mm),Tolerances on critical dimensions can be reduced to your requirements |

| Heat Treatment: | Selection according to material |

| Surface Finishing: | Include: Electroplated,Powder Coating,Laser Engraved Surfaces,High Energy Tumbling |

| applications: | Medical Manufacturing,Aerospace and Defense,Power transmission and gears,Smart home systems |