Advanced Powder Metal Technology and Customizable Sintered Parts Solutions for Your Project Needs

We strive to keep our advanced Powder Metallurgy manufacturing capabilities at the forefront of the industry. Whether you’re a product engineer or a buyer, you need to stay ahead of rapid industry change as the demand for new and better products keeps growing.Convert your products to powder metal to improve part strength and consistency.

Why choose powder metallurgy parts?

Powder Metallurgy Advantages

Lower Cost Metal Parts

Net Shape Capability,Low Required Energy

Ability to Mass Produce

Excellent Tolerances

Reliable Operating Hours

Powder Metallurgy Manufacturing Technology

Osweypm applies the following process for the manufacture and supply of powder metallurgy products.

- Sintered Parts: Batch manufacture of high-precision sintered parts by pressing and sintering processes.

- Metal Injection Moulding(MIM): It combines the freedom and flexibility of plastic injection moulding with the durability of metal materials.

Advanced powder metal manufacturing technology drives advanced manufacturing capabilities.

Over the past 14 years, Osweypm has accumulated Powder Metallurgy manufacturing technology,making more products with the least amount of raw material,minimise waste in the manufacturing process.We offer additional operations to refine the material properties or enhance precision.continuous improved processes that give Osweypm powdered metal components an edge over other parts in terms of long-term performance reliability in critical applications.We have a dedicated team that will follow the production process and keep you informed,eliminating the need for additional project management.

Quality Control

Quality Assurance

No Additional Management Required

High-Quality Parts Begin with High-Quality Metal Powders

Every quality metal part starts here. powder metal materials technology is an important factor in the durability of powder metal components.The right material choice resultsin higher density parts, higher productivity, and higher part-to-part consistency.

We ensure that the various metal powder materials we formulate are suitable for most products. Rigorous testing, analysis, and refinement by our engineers are important steps to ensure that the final metal powder material meets the customer’s requirements. These steps ensure that the strength, corrosion resistance, and mechanical properties of the metal powder material fully meet the requirements of your application.

Type of powder used can include iron based,stainless steel-based, copper based,non-ferrous, brass, bronze and other materials. Customized metal powder materials can also reduce your operating costs!

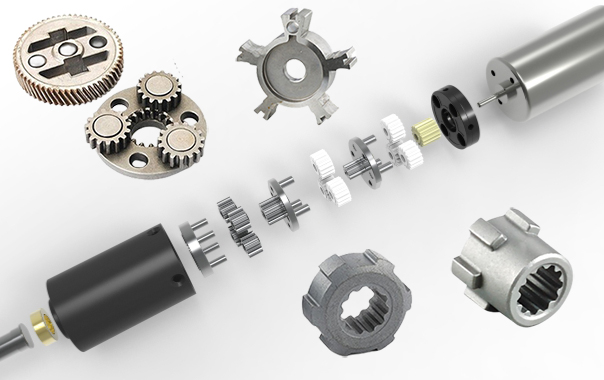

Powder Metallurgy - Sintering Parts(PM)

Metal Injection Molding(MIM)

Powder Metallurgy - Sintering Parts(PM)

Sintering Parts – increase the reliability of your components in continuous operation.

- In order to further improve economic efficiency, finding high-quality and low-cost parts is an important goal for many companies. Powder metallurgy utilizes scrap metal powders manufactured without the need for post-processing and close dimensional tolerances. Powder metallurgy’s good finish, high hardness, and net shape (cost savings) are the optimal combination of a variety of alloy systems and economic efficiency.

- Sintered parts are cost-effective because they use materials from scrap metal to create the powder. Sintering and secondary processing eliminate excess swarf and other waste, allowing the part to achieve excellent working performance.

- Sintered parts reduce your operating costs and give you a price advantage for your products, and we will work with you to develop customized and complex components by selecting the most suitable metal powder mixture for your application. We will also ensure that sustainable production methods are used to minimize the impact on the environment.

Metal Injection Molding(MIM)

Designed for structural flexibility and fine components,and offers a sophisticated look.

MIM begins with a polymerized metal feedstock containing tiny metal particles. Tiny metal powders are mixed with a binder to become granules, which are heated by injecting mixed granules into a mold cavity. The resulting part is considered a “green parts”. The part undergoes a degreasing process to remove polymers from the part. Finally, the parts are heated to high temperatures in a furnace to sinter the metal particles, resulting in a non-porous, almost completely dense part.

- The advantages of the MIM manufacturing process are highly consistent product performance and a smooth appearance. Ability to manufacture parts with irregular geometry.

- MIM injection molding can be applied to a wide range of metal materials, such as stainless steel, aluminum alloys, copper alloys, nickel alloys and so on.

- The degree of full densification after degreasing makes it have very good mechanical properties. Combined with the advantages of fully automated production by robots, the MIM manufacturing process is ideally suited for high volume production.

Discover your powder metal solution

Want to change your supply chain? We’ll get you the lowest cost.

We offer fully customizable solutions, from mold design evaluation and first samples to series production, we provide full engineering support to customers.

Customized Precision Machining

Custom Assembly Services

Customized Precision Machining

Rapid testing of your project at very low cost, and dimensional stability for high volume production

Can meet the requirements of advanced tolerances, advanced dimensions for PM or MIM is an extremely high challenge, especially when the product requires plating, PM and MIM can hardly meet the requirements, but our precision machining can do it, advanced tolerances as low as ±0.0008 in,Cylindrical grinding with tolerances up to ±0.00003 in.

Machining centers allow you to obtain a wide variety of parts or sub-assemblies from Osweypm’s,most of these parts come from our precision machining centers, with a few parts from Osweypm’s certified suppliers.

Centralized machining has significant cost benefits,the manufacturing process is fast, and accurate dimensions can be achieved in large quantities,tight tolerances are also an advantage of precision machining,and Osweypm machining centers can do the job of making parts ready to use right out of the box!

- Precision machining is the removal of removing small pieces of material from a workpiece. It machining focuses to machining parts with very flat , and smooth surfaces , ensuring they meet very tight tolerances.

Materials we can process include:iron, stainless steel, aluminum, copper, titanium, steel, plastic and more - Outside capabilities range from Grinding,Drilling, Tapping, Honing, Milling,Lapping, Turning, Hard Turning, Reaming,high energy tumbling, other customized processing.

- Surface Finishing include:Plating,Blackening Coating,Heat Treating,Powder Coating and Laser Engraved Surfaces,many more.

- Precision machining is the removal of removing small pieces of material from a workpiece. It machining focuses to machining parts with very flat , and smooth surfaces , ensuring they meet very tight tolerances.

Custom Assembly Services

Optional assembly: assembly of metal parts to each other,assembly of plastics to metals.

Each part will have a certain tolerance when it is manufactured, but the constant accumulation of tolerances during assembly makes it difficult to assemble the whole machine.

Pre-assembly can be assembled according to the tolerance required by the customer, reduce or eliminate the assembly tolerance as much as possible, detect or correct the error in advance, guarantee your whole machine assembly smoothly, thus saving your time and money.